Hot dipped galvanised coil is a product that features revolutionised the steel business.

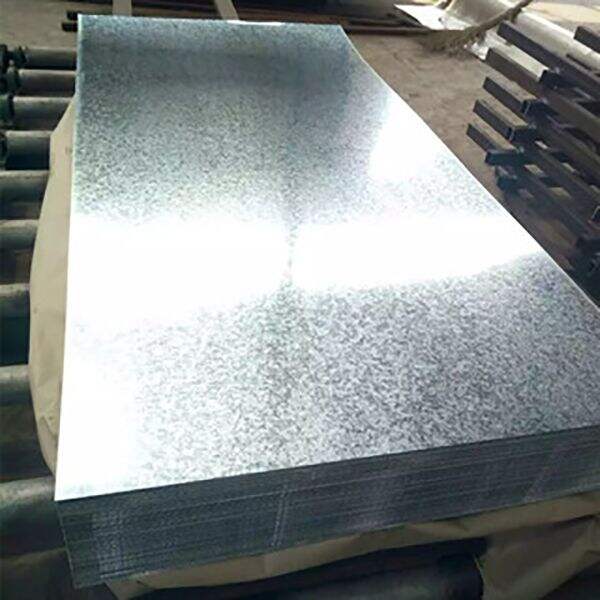

ROGO hot dipped galvanised coil is a type of steel coil which has been dipped in a bath of molten zinc to generate a protective coating.

This product has many advantages uses in the numerous industries.

Hot dipped galvanised coil is unique steel has a coating of zinc.

It really is super helpful and that can be properly used in lots of different ways.

Hot dipped galvanised coil is steel that it gets dipped in hot molten zinc.

This produces a protective layer causes it to be super valuable in various industries.

Among the main advantages of hot dipped galvanised coil is that the zinc coating provides corrosion excellent protection.

These will it is making perfect for the use within harsh environments where traditional steel quickly rust and deteriorate.

Additionally, hot dipped galvanised coil has a strength-to-high weight, making it an even more cost-effective substitute for other types of steel.

Hot dipped galvanised coil has a special coating of this in it stops it from rusting.

ROGO hot dipped galvanized steel coils may ensure it is super beneficial in places where regular metal break and rust.

Additionally it is really strong.

Hot dipped galvanised coil is awesome because it generally will not rust easily.

This makes it perfect for usage in harsh areas on metals.

Plus, it's strong and can take a complete large amount of weight without breaking.

Hot dipped galvanised coil has been through many innovations in recent years.

Advances in technology are to be able to use the zinc layer most precisely, ensuring the particular highest level of protection and durability.

Also, new manufacturing practices have made hot dipped galvanised coil less expensive and accessible, setting up its use in many different applications.

Hot dipped galvanised coil has gotten better with time.

New technology has made it even stronger and longer-lasting.

Plus, it really is smoother to make much less expensive, so more somebody can use it.

Hot dipped galvanised coil has improved a great deal recently due to new technology manufacturing techniques.

ROGO hot dipped steel coil really is now more durable and precise, and also less expensive, this means it can become used in more places.

hot dipped galvanised coil can be utilized in many different applications, including construction, automotive manufacturing, and appliance of the production.

When using hot dipped galvanised coil, it’s important to deal with it with care in order to prevent damaging the protective coating.

Additionally, proper storage and handling can make sure that this product remains in good condition, ready for usage when the recommended.

Hot dipped galvanised coil could be used to help make buildings, cars, and appliances.

You must be careful when working with it so you don't damage the finish that has been unique.

Make sure you store it in a safe area.

Hot dipped galvanised coil can be utilized in large amount things such as buildings, cars, and equipment.

It's important to handle it carefully which means you do not scrape the final.

And stays ensure in a safe ROGO prime hot dipped galvanized steel coils it remains in good shape.

Rogosteel provide wide range products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. Customized services are available in 1825 colors RAL as well custom-designed colors for customers.product hot dipped galvanised coilfor many different applications corrugated boards, such as glazed tiles/sandwich panel/home appliances, power supply cabinets/keels.Some examples of relevant cases are the construction of port facilities in the Middle East, government engineering procurement airports of huge size located Eastern Europe.

Rogosteel certified to the ISO9001 quality management system, ISO14001 environmental management system, OHSAS18001 occupational healthcare management system, SGS/BV other certifications. Raw materials for substrates for products are sourced from Tangshan Iron and Steel and HBIS. paints used in the production process manufactured by internationally recognized brands like AKZO and PPG. The technology used in the product is high-end production lines that are imported from Germany Fully enclosed production workshops, as well as rigorous quality control. production line is overseen by experts in the hot dipped galvanised coil quality inspectors, in real-time. rate of passing testing of the product is 100 100%.stock a wide range of instruments, including: board flattening machines, defects detectors, as well as ultraviolet resistance testing equipment. Warranty of 15 years.

Rogosteel has nine production lines with an annual output 2,000,000 tons and has made long-term strategic agreements with more than 20 expert logistics agents major domestic customs brokers for ports to ensure the effectiveness shipping cargo. We are able to work with our customers process various testing certificates and certification the document of customs clearance to ensure the delivery their goods. includes the BV certificate, CO Embassy certification, more.company has a professional after-sales hot dipped galvanised coilthat monitors the after-sales process throughout the process. They are available 24 hours a day. Within 12 hours, the business will respond to any after-sales problems and offer solutions within 24 hours.

an hot dipped galvanised coilfocused on exports, ROGOSTEEL has focused over past decade on improving product quality and promoting services. ROGOSTEEL has developed collaborative relationship with over 500 customers across Asia, Europe and South America. company also has earned a reputation for their pragmatic approach integrity.company has been awarded "Shanghai Best Export Enterprise" and China Inspection-Free Products" as well as "Alibaba Outstanding Trade" over a period of time. The client satisfaction rating is 100%.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy