1. Introducing Prime Hot Dipped Galvanized Steel Coils

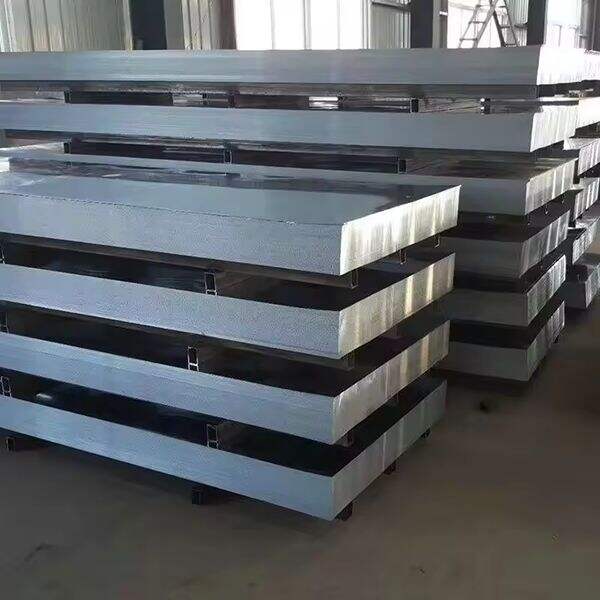

Prime hot dipped galvanized steel coils ROGO are special steel products that undergo a set of processes to strengthen their durability, corrosion resistance, and power. These are typically widely preferred in industrial and construction hot dipped galvanized steel coils settings due to their advantages being numerous. These steel coils are made by dipping steel sheets or coils into a bath of molten zinc, which produces a protective layer the steel preventing rust as well as other forms of corrosion. We shall explore the advantages of hot dipped galvanized steel coils, safety precautions whenever using them, plus some given information about how to work with them.

Among the main importance is the durability. They could withstand harsh environments and extreme weather without corroding or weakening. This means ROGO that they could last for decades without needing repairs or replacements, which ultimately saves cash on maintenance costs.

Another advantage of these steel coils is the corrosion resistance. They do not rust or corrode easily, even yet in high moisture or wet surroundings they have been coated with zinc. This makes them ideal for outdoor prime hot dipped galvanized steel coils structures such as roofing, fences, and guardrails.

Prime hot dipped galvanized steel coils are also extremely strong. They are able to withstand hefty loads stresses without breaking or bending. This makes them ideal for used in construction, where stability and strength are crucial.

In modern times, there have already been innovations that could be several the production of prime hot dipped galvanized steel coils. One such innovation the ROGO introduction of high-strength steel coils, which have even greater durability and strength than traditional steel coils.

Another innovation could be the utilization of high level electronic technology track and control galvanized coil steel the coating process. This ensures that the steel coils get a consistent, uniform coating, which enhances their corrosion resistance and durability.

When handling and installing prime hot dipped galvanized steel coils, it is crucial to observe safety precautions to prevent accidents and injuries. A number of the ROGO safety measures to believe about include wearing protective clothing as gloves, helmets, and safety glasses. It's also wise to make sure galvanized steel you use appropriate tools and gear when it comes to working job avoid overloading the coils beyond their rated capacity.

Rogosteel provide wide range of products, including galvanized/galvanized/color-coated steel coil (including matt ppgi /embossed ppgi/home appliance panel), roofing sheets, cold rolled aluminum coil. We offer custom-designed services. RAL colors and custom-designed colors readily available.product is ideal to be used in a range of different ways, including corrugated board/glazed tiles/sandwich panel/home appliances, prime hot dipped galvanized steel coilssupply cabinets/keels.Relevant examples are the construction of ports in Middle East, government engineering procurement and airports of huge size Eastern Europe.

Rogosteel's nine production lines that produce annual output that exceeds 2,000,000 tons have also established long-term strategic agreements more than 20 professional logistic agents a the largest customs broker for ports in the country to ensure the efficiency shipping cargo. Based on national policy requirements can collaborate with processing of various tests and certification certificates in documentation for customs clearance of goods delivery, including the BV prime hot dipped galvanized steel coils, CO embassy certification, etc. professional team of after-sales experts is available throughout the day, all year round to ensure the service is being monitored. After-sales issues will be addressed within 12 hours and initial solutions are provided within 24 hours.

an export oriented enterprise, ROGOSTEEL has focused over last decade on enhancing the quality of its products promoting services. Through efforts of all staff members, ROGOSTEEL have built cooperative relationship with nearly 500 customers from 100 countries in Asia, Europe, South prime hot dipped galvanized steel coils, Oceania and Africa has earned a strong reputation their honesty and pragmatic method of operation.In 2014, business has passed ISO9001 quality and management system certification with KS certification. Additionally, it has SGS and BV testing certificates, and has been awarded "Shanghai's Most Export-oriented Enterprise", "China Inspection-Free Products" and "Alibaba Excellent Trade" for many consecutive years Businessmen". The customer satisfaction rate is 100%.

Rogosteel certified to the ISO9001 Quality Management System, ISO14001 environmental management system OHSAS18001 occupational safety health management system, SGS/BV as well as other certifications. The raw materials of the product substrates come from Tangshan Iron Steel and HBIS and paints use internationally renowned brands like AKZO and PPG. The product's technology based on modern production lines that are imported from Germany with fully enclosed production workshops, as well as strict quality control. The production line is monitored by experts in field quality inspectors in real-time. pass rate of finished testing of the product is 100 percent. offer instruments like zinc layer dynamic monitoring equipment, defect detectors board flattening equipment and UV resistance testing equipment. Warranty 15 years.

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy