Overview:

Galvanized Steel Coil, manufactured by Rogosteel, utilizes cold-rolled steel coil as a substrate that undergoes a continuous hot-dip process. This method creates a tightly bonded alloy layer of zinc and iron, providing excellent corrosion resistance, paintability, and workability.

Specifications:

| GI Galvanized Steel | |||

| Brand: | Rogosteel | Place of Origin: | Shandong, China |

| Thickness: | 0.2-1.5mm | Width: | 600-1250mm |

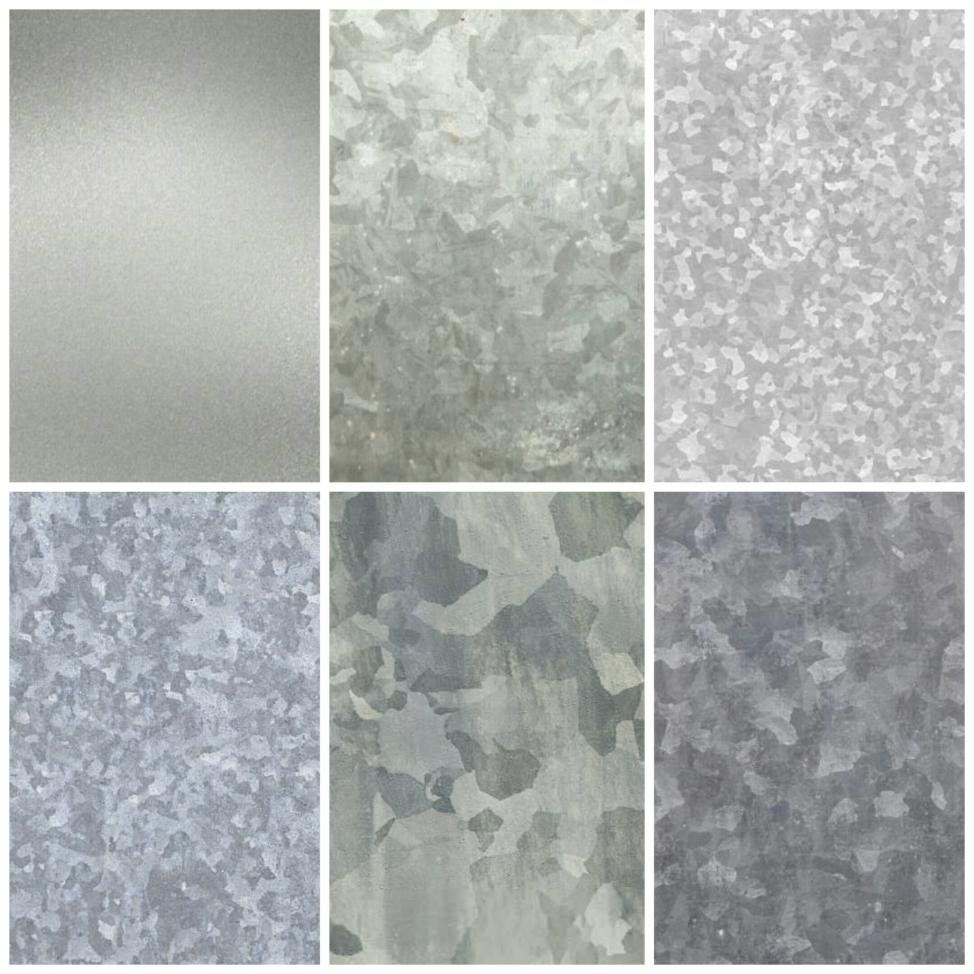

| ZincCoating: | 40-275g/m2 | Spangle: | Regular/Minimum/Zero/Big |

| Standard: | ASTM A653/GB/JIS | Grade: | SGCC/SGCH/DX51D/DX52D/DX53D |

| Surface Treatment: | Chromated/non-chromated,Oiled/non-oiled | Technique: | Hot Dipped |

| Coil Weight: | 3-8Tons | Type: | Coil/Sheet/Strips/Plate |

| Certificates: | ISO9001-2008,SGS,BV | Supply Ability: | 2000000 tons per year |

| MOQ: | 25 tons per size | Delivery Time: | 15-20 work days |

| Packaging: | Standard Sea-worthy Packing | Payment term: | T/T ,L/Cat sight |

| Brand: | Rogosteel | Place of Origin: | Shandong, China |

| Thickness: | 0.2-1.5mm | Width: | 600-1250mm |

| ZincCoating: | 40-275g/m2 | Spangle: | Regular/Minimum/Zero/Big |

| Standard: | ASTM A653/GB/JIS | Grade: | SGCC/SGCH/DX51D/DX52D/DX53D |

Production Capacity:

Rogosteel operates a state-of-the-art production line with:

- Annual Capacity: 200,000 tons

- Manufacturing Speed: 150m/min

- Production Standards: EN 10346, ASTM A653

Features:

- Corrosion Resistance: Enhanced by the zinc coating, suitable for outdoor applications.

- Paintability: Surface allows for easy and effective painting.

- Workability: Ideal for forming and fabrication processes in various industries.

Applications:

- Metal Roofing: Durable solution for residential and commercial roofs.

- Steel Coil Applications: Widely used in automotive, construction, and appliance industries.

Surface Treatments:

- Chromic Acid Treatment: Provides corrosion resistance, suitable for bare conditions.

- Phosphoric Acid Treatment: Enhances paint adhesion and corrosion resistance.

- Oiling: Prevents rust during storage and transportation.

Types of Zinc Coating:

- Pure Zinc Coating: Provides basic corrosion protection.

- Zinc-Iron Alloy Coating: Offers superior weldability and heat resistance.

Did you know leading home appliance brands are upgrading their products using PCM, VCM, and high-end PPGI steel to achieve better durability and a premium look?

✅ PCM (Pre-coated Metal) – Provides a sleek, corrosion-resistant finish for refrigerators, washing machines, and more.

✅ VCM (Vinyl Coated Metal) – Offers stylish patterns and colors for modern appliance designs.

✅ High-end PPGI – Ensures long-lasting performance in challenging environments.

At Rogosteel, we supply high-quality appliance-grade steel to manufacturers worldwide, helping you stay ahead of the competition.

Explore more: https://www.hkrogosteel.com/

Fast delivery and efficient logistics are essential for a seamless supply chain. At Rogosteel, we make it easy to get the materials you need when you need them.

✅ Quick Shipments – We partner with trusted logistics providers to ensure on-time delivery.

✅Flexible Transport Options – Sea, land, or air freight tailored to your needs.

✅Customs Support – Professional clearance services to ensure safe arrival of goods.

With Rogosteel, your projects stay on schedule.

Learn more: https://www.hkrogosteel.com/

Our mission at Rogosteel is to be your trusted steel supplier worldwide. With 9 steel lines, 5 color-coated lines, and 1 advanced Galvalume line, we provide high-quality products for construction and home appliances.

What makes us stand out?

✅ Commitment to Quality – Every coil is rigorously inspected.

✅ Customer First – Trusted by 500+ clients in 100 countries.

✅ Product Innovation – Offering GI, GL, PPGI, PCM, and VCM solutions.

Your success is our story. Let’s grow together.

Discover more: https://www.hkrogosteel.com/

Client feedback matters to us. A customer from South America, shared his experience working with Rogosteel:

"We use Rogosteel’s PPGI and PCM steel for our home appliance production. The materials are high-quality, with a wide range of color options. Plus, their logistics service is excellent. Rogosteel is a reliable partner!"

Why choose Rogosteel?

✅ High corrosion resistance

✅ Stylish and durable finishes

✅ Perfect for appliance applications

Join our growing network of satisfied clients.

Contact us: https://www.hkrogosteel.com/

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy