|

Pre-Painted Galvanized Steel Coil (PPGI) and Pre-Painted Galvalume Steel Coil (PPGL) is a kind of building materials, with galvanized sheet and aluzinc sheet as the substrate, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then firing and cooling, finally the palte steel is called pre-painted galvanized steel coil (PPGI) or pre-painted galvalume. PPGI/PPGL Perpainted Galvanized/Galvalume Steel | |||

Brand: |

Rogosteel |

Place of Origin: |

Shandong, China |

Thickness: |

0.2-1.5mm |

Width: |

600-1500mm |

ZincCoating: |

40-275g/m2 |

Painting: |

Top 15-40μm,Back 5-20μm |

Standard: |

ASTM A653/GB/JIS |

Grade: |

SGCC/CGCC/DX51D+Z |

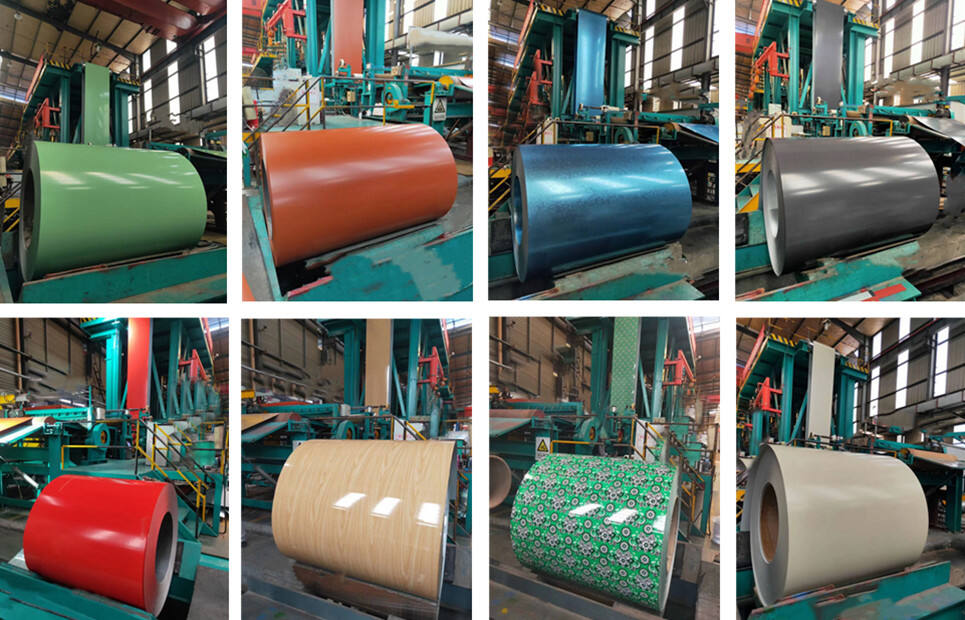

Color: |

All Ral Color or As Request |

Technique: |

Cold Rolled |

Coil Weight: |

3-8Tons |

Type: |

Coil, Sheet, Strips, Plate |

Certificates: |

ISO9001-2008,SGS,BV |

Supply Ability: |

2000000 tons per year |

MOQ: |

25 tons per size |

Delivery Time: |

15-20 work days |

Packaging: |

Standard Sea-worthy Packing |

Payment term: |

T/T ,L/Cat sight |

As the layer bears different colors, it is also known as color coated steel sheet. Through the combined use of diverse paints and base substrates, we select colors and material properties that meet the specific needs.

Painting information as following:

Top Paint: PVDF, HDP, SMP, PE(Polyester), PU.

Prepainted Galvanized Steel Coil has many functions like decorative (color ) machinability, weather resistance, scratch resistance, stain resistance, chemical resistance and adhesion resistance.

Primer Paint: Polyurethane, epoxy, PE.

The functions of this layer including machinability, corrosion resistance, adhesion and scratch resistance.

Back Paint: Epoxy, modified polyester.

ROGOSTEEL is a prepainted steel coil supplier and manufacturer in China. We supply all RAL colors and special patterns can be made, such as wood grain, flower print, camouflage, and brick.

We manufacture thickness is 0.13-0.8 mm, width is 600-1250 mm, and PE, SMP, and PVDF painted steel coil to meet customer needs.

Top Finish Coating (PE/HDP/PVDF, etc.), When the thickness is above 20um, it can effectively prevent the damage of ultraviolet rays and harsh environments to the coating.

Primer Coating

Surface Treatment Layer(Chromate Coating)

Metallic Coated Layer (Zn, AL, 55%AL+Zn)

Steel Substrate (Cold Rolled Steel Sheet)

Metallic Coated Layer (Zn, AL, 55%AL+Zn, Sn, Cr, etc.)

Surface Treatment Layer (Chromate Coating)

Back Primer

Back Finish Coating(Epoxy, Polyester )

The top coating is larger than 20μm to prevent the intrusion of corrosive media. Due to the different anti-corrosion mechanisms of primer and finish coating, not only the total coating thickness should be guaranteed, but also the thickness of primer (>5μm) and finish coating (>15μm).

PVDF pre-painted steel coil requires a thicker coating. It provides a longer service life. The requirements for the backside paint coating depend on the application, and the sandwich panel only requires a layer of primer. The formed steel plate requires two coats. The thickness is at least greater than 10 μm.

The protective film is a transparent or colored plastic film coated on the surface of the pre-painted galvanized steel coil. The purpose is to prevent scratches on the painted surface paint during cold roll forming. Our plastic film thickness is 30 microns, 40 microns, 50 microns, 60 microns, and 80 microns.

The metallic coating of color coating for construction is hot-dip galvanized. The greater the thickness of the metallic coating, the better the corrosion resistance.

The thickness of the metallic coating mainly affects the cut corrosion performance of the pre-painted galvanized steel coils, and the influencing factors include the finish coating, primer, substrate thickness, and metallic coating thickness.

We produce pre-painted steel coils for galvanized steel substrates with metallic coating of G40, G60, and G90. Please select the appropriate one according to the use environment.

We mainly use PE, SMP, and PVDF three kinds of coatings to produce PPGI Coil.

Polyester (PE) coating is suitable for ordinary residential roofing, the price is the cheapest, and it cannot withstand harsh environments. Silicone Modified Polyester (SMP) coating contains high weathering and super high weathering paints which can be applied in areas of high heat and cold, humid heat, and extreme cold. Polyvinylidene Difluoride (PVDF) coating has strong corrosion resistance, strong heat resistance, and the highest price. It is used in countries with humid heat, high temperatures, s and more rain.

We work with beckers, Valspar, and Akzo.

Application:

Constructions: Roofing, wall, water fender, warehouse walls, doors, shells etc.

Household appliances: Refrigerator, washer, shower, dust collector etc.

Auto Industry: Car shell, spare parts, oil box, water box etc.

Did you know leading home appliance brands are upgrading their products using PCM, VCM, and high-end PPGI steel to achieve better durability and a premium look?

✅ PCM (Pre-coated Metal) – Provides a sleek, corrosion-resistant finish for refrigerators, washing machines, and more.

✅ VCM (Vinyl Coated Metal) – Offers stylish patterns and colors for modern appliance designs.

✅ High-end PPGI – Ensures long-lasting performance in challenging environments.

At Rogosteel, we supply high-quality appliance-grade steel to manufacturers worldwide, helping you stay ahead of the competition.

Explore more: https://www.hkrogosteel.com/

Fast delivery and efficient logistics are essential for a seamless supply chain. At Rogosteel, we make it easy to get the materials you need when you need them.

✅ Quick Shipments – We partner with trusted logistics providers to ensure on-time delivery.

✅Flexible Transport Options – Sea, land, or air freight tailored to your needs.

✅Customs Support – Professional clearance services to ensure safe arrival of goods.

With Rogosteel, your projects stay on schedule.

Learn more: https://www.hkrogosteel.com/

Our mission at Rogosteel is to be your trusted steel supplier worldwide. With 9 steel lines, 5 color-coated lines, and 1 advanced Galvalume line, we provide high-quality products for construction and home appliances.

What makes us stand out?

✅ Commitment to Quality – Every coil is rigorously inspected.

✅ Customer First – Trusted by 500+ clients in 100 countries.

✅ Product Innovation – Offering GI, GL, PPGI, PCM, and VCM solutions.

Your success is our story. Let’s grow together.

Discover more: https://www.hkrogosteel.com/

Client feedback matters to us. A customer from South America, shared his experience working with Rogosteel:

"We use Rogosteel’s PPGI and PCM steel for our home appliance production. The materials are high-quality, with a wide range of color options. Plus, their logistics service is excellent. Rogosteel is a reliable partner!"

Why choose Rogosteel?

✅ High corrosion resistance

✅ Stylish and durable finishes

✅ Perfect for appliance applications

Join our growing network of satisfied clients.

Contact us: https://www.hkrogosteel.com/

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy