Overview:

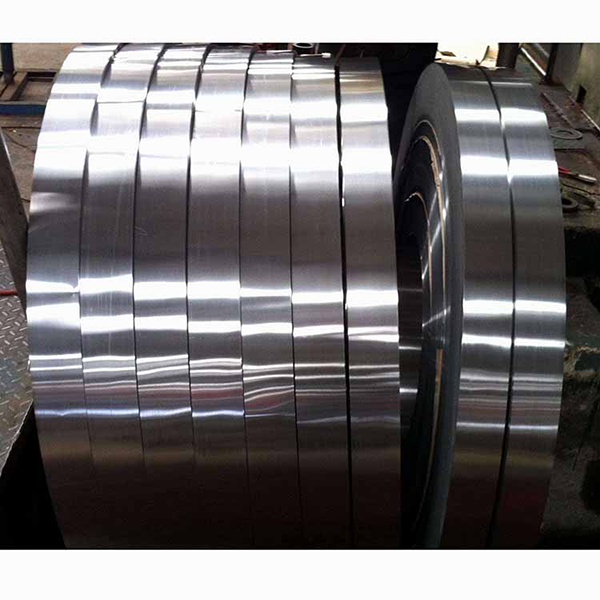

Rogosteel's Galvanized Steel Strip is produced using advanced continuous production lines for pickling, cold rolling, and hot-dip galvanizing. With an impressive annual capacity of 2 million tons, we manufacture galvanized strips, pickling strips, and cold-rolled strips with precise specifications to meet diverse industrial requirements.

| Galvanized Steel Strip | |

| Regular spangle Thickness(mm) | 0.3-5.0 |

| Zero spangle Thickness(mm) | 0.6-1.8 |

| Width(mm) | 32-860 |

| Coating Weight(g/square meter) | 50-600 |

| Inner diameter(mm) | 508/610 |

| Surface structure | Regular spangle,Zero spangle |

| Surface treatment | Environmental chromated,Regular chromated |

| Yield Strength | 195~500MPa |

| Tensile Strength | 315~600MPa |

| Elongation | ≥10% |

Production Process:

The production process of our Galvanized Steel Strip involves rigorous procedures to ensure optimal quality:

1. Pickling:Removes contaminants from the steel surface.

2. Cold Rolling:Achieves the desired thickness and smooth surface.

3. Hot-Dip Galvanizing:Zinc coating applied through immersion in molten zinc.

4. Finishing:Ensures uniform coating thickness and surface quality.

Uses:

Galvanized Steel Strip finds extensive application in:

Construction:Structural components, roofing, siding.

Light Industry:Automotive parts, appliances, HVAC ducts.

General Manufacturing:Electrical enclosures, industrial machinery.

Storage and Maintenance:

- Store in a dry environment to prevent corrosion.

- Avoid prolonged exposure to sunlight to maintain zinc coating integrity.

Quality Control:

Stringent quality checks ensure product reliability:

- Visual inspection for surface appearance and dimensions.

- Thickness measurement of zinc coating.

- Mechanical tests to verify strength and ductility.

How to Choose:

Consider specifications such as thickness, width, and coating weight based on application requirements. Verify surface condition and zinc layer thickness for optimal corrosion resistance. Choose between light or heavy oiling based on environmental and processing needs.

Conclusion:

Rogosteel's Galvanized Steel Strip offers superior corrosion resistance and durability, making it ideal for diverse industrial applications. Backed by advanced manufacturing processes and stringent quality controls, our products meet the highest industry standards.

Did you know leading home appliance brands are upgrading their products using PCM, VCM, and high-end PPGI steel to achieve better durability and a premium look?

✅ PCM (Pre-coated Metal) – Provides a sleek, corrosion-resistant finish for refrigerators, washing machines, and more.

✅ VCM (Vinyl Coated Metal) – Offers stylish patterns and colors for modern appliance designs.

✅ High-end PPGI – Ensures long-lasting performance in challenging environments.

At Rogosteel, we supply high-quality appliance-grade steel to manufacturers worldwide, helping you stay ahead of the competition.

Explore more: https://www.hkrogosteel.com/

Fast delivery and efficient logistics are essential for a seamless supply chain. At Rogosteel, we make it easy to get the materials you need when you need them.

✅ Quick Shipments – We partner with trusted logistics providers to ensure on-time delivery.

✅Flexible Transport Options – Sea, land, or air freight tailored to your needs.

✅Customs Support – Professional clearance services to ensure safe arrival of goods.

With Rogosteel, your projects stay on schedule.

Learn more: https://www.hkrogosteel.com/

Our mission at Rogosteel is to be your trusted steel supplier worldwide. With 9 steel lines, 5 color-coated lines, and 1 advanced Galvalume line, we provide high-quality products for construction and home appliances.

What makes us stand out?

✅ Commitment to Quality – Every coil is rigorously inspected.

✅ Customer First – Trusted by 500+ clients in 100 countries.

✅ Product Innovation – Offering GI, GL, PPGI, PCM, and VCM solutions.

Your success is our story. Let’s grow together.

Discover more: https://www.hkrogosteel.com/

Client feedback matters to us. A customer from South America, shared his experience working with Rogosteel:

"We use Rogosteel’s PPGI and PCM steel for our home appliance production. The materials are high-quality, with a wide range of color options. Plus, their logistics service is excellent. Rogosteel is a reliable partner!"

Why choose Rogosteel?

✅ High corrosion resistance

✅ Stylish and durable finishes

✅ Perfect for appliance applications

Join our growing network of satisfied clients.

Contact us: https://www.hkrogosteel.com/

Copyright © ROGO INDUSTRIAL (SHANGHAI) CO.,LTD All Rights Reserved - Privacy Policy