Introduction

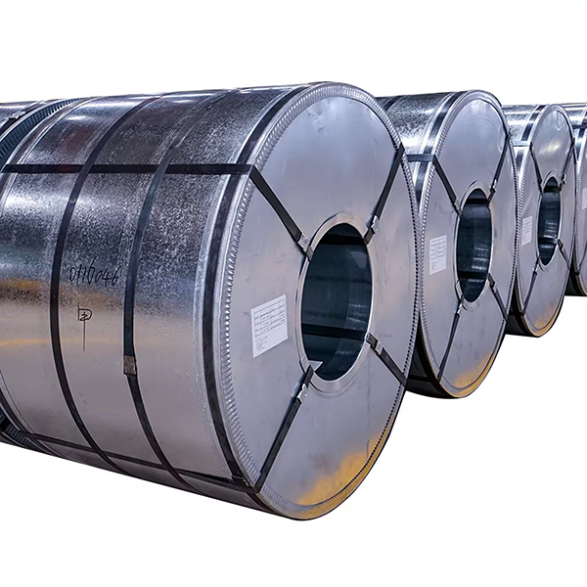

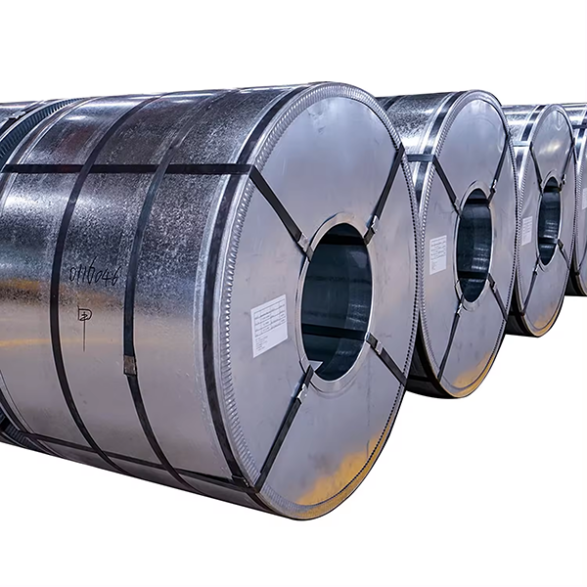

Galvanized steel coils must meet specific industry standards to ensure quality, durability, and suitability for various applications. These standards specify the chemical composition, mechanical properties, and coating thickness.

Key Standards for Galvanized Steel Coils

ASTM A653/A653M: This is a common standard in the United States for hot-dip galvanized coils. It specifies the coating designation (G30, G40, G60, G90) and the mechanical properties, including yield strength (230-550 MPa) and tensile strength (270-700 MPa).

EN 10346: The European standard covers the requirements for continuously hot-dip coated steel flat products. It includes a variety of coating types such as Z (Zinc), ZA (Zinc-Aluminum), and AS (Aluminum-Silicon).

JIS G3302: In Japan, this standard defines the specifications for hot-dip galvanized steel sheets and coils, with a focus on coating mass, ranging from Z12 to Z60.

ISO 3575: This international standard specifies the requirements for continuously hot-dip zinc-coated low-carbon steel sheets and coils.

Coating Thickness and Weight

The coating thickness directly influences the product's durability. It is typically measured in microns, with 275g/m² being a common high-end specification for outdoor applications.

Surface Finish

Galvanized coils come in different finishes, including regular spangle, minimized spangle, and zero spangle, depending on aesthetic requirements.

Mechanical Properties

Typical properties include yield strength (ranging from 180 to 550 MPa) and elongation (ranging from 20% to 40%), ensuring the material's suitability for forming and other processes.

Conclusion

Understanding the standards for galvanized steel coils is crucial for selecting the right product for your application. These standards ensure that the material will perform as expected under specified conditions.