Introduction

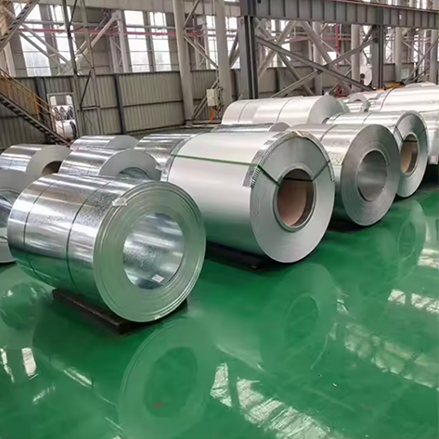

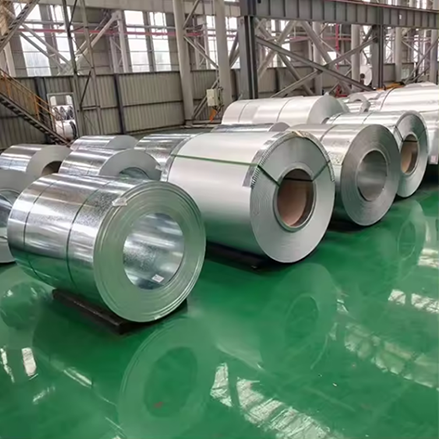

Aluzinc coils are widely used in various industries for their exceptional resistance to corrosion, heat, and weathering. This comprehensive guide explains what Aluzinc is, its composition, and why it is preferred over other materials in demanding applications.

Material Composition

Aluzinc is an alloy composed of 55% aluminum, 43.4% zinc, and 1.6% silicon. This unique combination provides the material with enhanced durability and corrosion resistance, making it suitable for extreme environmental conditions.

Key Properties of Aluzinc Coils

·Corrosion Resistance: The aluminum in Aluzinc forms a protective layer that shields the underlying steel from corrosion, while the zinc provides a galvanic protection.

·Thermal Resistance: Aluzinc can withstand high temperatures, making it ideal for applications requiring heat resistance.

·Aesthetic Appearance: Aluzinc offers a bright, reflective surface that is aesthetically pleasing, with the option of regular or minimized spangle finishes.

·Formability: Aluzinc coils are easy to form and shape, making them suitable for a variety of applications, including roofing, cladding, and industrial components.

Technical Specifications

·Thickness Range: Aluzinc coils are available in thicknesses from 0.25mm to 2.0mm.

·Coating Mass: AZ50 to AZ185, offering different levels of protection based on application needs.

·Width: Standard widths range from 600mm to 1500mm, customizable according to client requirements.

Applications

·Roofing and Cladding: Ideal for coastal and industrial environments where corrosion resistance is critical.

·HVAC Systems: Used in the manufacturing of ducts and components due to its high thermal resistance.

·Automotive Industry: Preferred for underbody components and other parts exposed to harsh conditions.

Conclusion

Aluzinc coils offer a versatile and durable solution for industries that require materials with high corrosion and heat resistance. Understanding its properties and applications can help in selecting the right material for your specific needs.