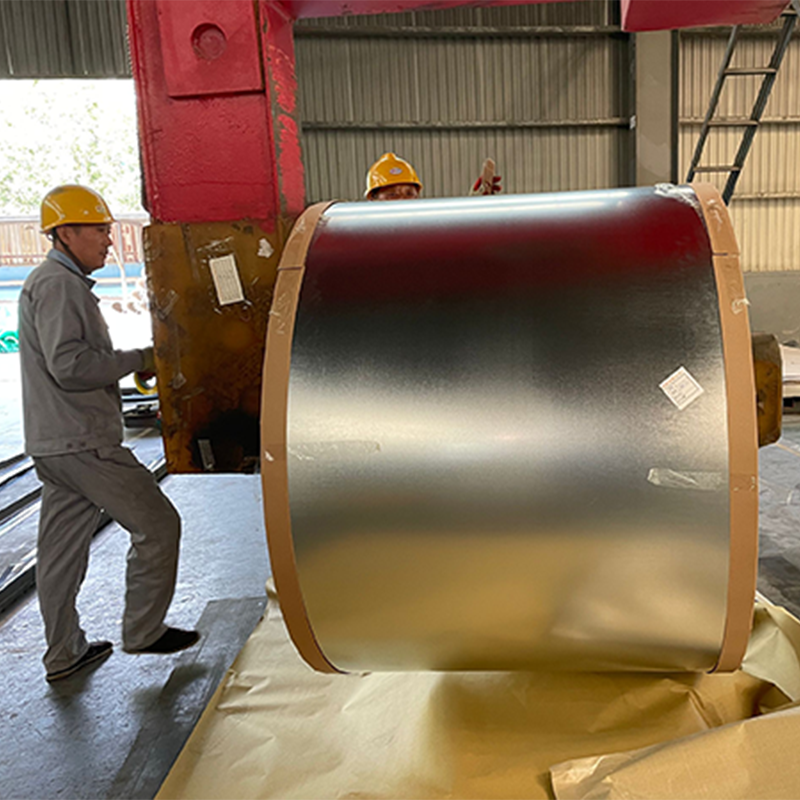

It is a very important raw material of cold rolled Gi coil, which cannot be ignored in the construction and manufacturing industries. The other development happening here is the material itself as this is some of that cutting edge technology and new age materials science stuff going on which speaks to more than just strength but sustainability. This product by ROGO, which features the strong cold rolled steel nucleus fortified by a protective zinc base layer is emblematic of what mortals manage to achieve when designing structures for excellence in corrosion resistance.

Zinc Coating: The Magical Power to Keep the Long Last Structures

Cold rolled steel cannot disappear from the day and all natural effects on zinc coated proactive steel. It is an ideal defender against moisture and oxygen, the two culprits that initiate rust-streaking through galvanization structure where zinc oxide with steel substrate. Coupled with the sacrificial nature of zinc (whereas zinc is consumed before steel in service to protect what lays beneath) and a passive layer, structures constructed from Gi coil will certainly outlast those built from uncoated materials. It is a strategic investment with longevity and offers the best solution to projects which require high resilience in harsh environments.

Influence of surface pretreatment on optimal weather performance cold rolled steel with electro-deposition zinc coated

Galvanized steel has a zinc covering to deter rust along the surface edge only, while zinc coating is effective for defense beyond this open exterior. It converts the relative cold rolled steel to a new structure where nature rain or shine can do little damage/harm. No matter how hot the temperature goes or how cold it becomes, that gi steel coil will still look and feel like one. This dense layer of bonded zinc forms a barrier that is impervious to UV rays which provide up to an average five or better service life against corrosion than what G90 coatings are rated for. and, on non-exposed areas, resists the onset rust. When you add a zinc coating to the cold rolled steel, from being most ductile of material it becomes one that can do better for use in these tests no matter where situated South or North Pole and lets buildings and bridges etc. maintain its strength over decades.

Stocking Zinc Coated Cold Roll for Expedited Jobs

In an industry where time is money and supply needs are more sudden than predictable, it makes sense to have a steady in-house source of Zn coated cold rolled coils. Offering our innovative materials for immediate availability accelerates project schedules, supporting ad-hoc construction requirements or emergency fixes. It can order the works from small renovations to critical infrastructure projects, and it is all accomplished by precisely because you have Gi Steel Coil in hand so that downtimes are minimized. That quick crash is there so developers can prompt the availability of actions for you on their projects and still get done in a timely manner without cutting short-circuit.

Application: construction, automotives and every other area Use of Gi Coil

Ideal for user across a multitude of industries, this zinc coated cold rolled Gi coil will prove the optimal cost/performance profitability ratio lightweight breathable material that is also fire and heat resistant; In construction, concrete is an extremely important material to finish the roofing, cladding and increase its overall strength. There are several materials in demand that would rely on Gi sheets which have incredible strength-to-weight ratios, such as the automotive industry with body panels and undercarriage parts where weight is a large concern or even interior features. In addition, these coils are also well-suited to other sectors such as consumer durables, solar power etc. making Gi the perfect choice for several functional and design needs apply over diverse segments. These varied applications demonstrate how indispensable this material has become in the schemes of modern production.

Next Post The Sustainable Truth Behind Zinc Coated Steel

In a world that demands eco credentials influencing specifications, zinc coated steel is often the ideal sustainable option. Given Gi coils are long-life products, their re-use means a longer time before they reach end-of life. Thus, with the recycled content of zinc and steel in them, though others pick-up post-consumed material credits as well without any deterioration of quality at end-of- because `circle economy' should start here. Moreover, the lifespan of zinc-coated structures was longer so maintenance and replacements were lesser (a carbon renewability cut with recycling) reducing continuous manufacturing and construction. Architects and builders can make a substantial impact on climate change by specifying long-lasting, strong building products like zinc coated steel.

Cold-rolled GI coil zinc-coated is nothing more than a harmonious balance between utility and longevity with that dash of social responsibility. This is the infrastructure and in an alive embodiment for how they can now be implemented on top of that old materials base, to allow you experience not only great corrosion stability but genuinely innovative-, off-the-shelf- and ecofriendly solutions. Installed today and reaching towards the prospect of future construction, zinc coated steel thus anchors our material toolbox as a foundation for contemporary life to exist on - following where nature dictates.

Table of Contents

- Zinc Coating: The Magical Power to Keep the Long Last Structures

- Influence of surface pretreatment on optimal weather performance cold rolled steel with electro-deposition zinc coated

- Stocking Zinc Coated Cold Roll for Expedited Jobs

- Application: construction, automotives and every other area Use of Gi Coil

- Next Post The Sustainable Truth Behind Zinc Coated Steel