Step in PPGI and PPGL Coating

In the world of two important coats that are required for shielding steel sheets.

Understanding PPGI

The zinc coating contribute to rust layer is not present and therefore high tensile steel will prevent from corroding using the traditional means called pre-painted galvanized iron (PPGI). Then they are painted with a high-quality special paint for color and texture, thus giving to the boards both strength that allows you to build buildings from them, as well as appearance.

Insight into PPGL

This is where Pre-painted Galvalume steel (PPGL) instead differs from standard galvanized components as it mixes aluminum and zinc to formulate a protective coating named Galvalume. This unprecedented mixture offers a more elevated amount of erosion resistance than standard galvanized coatings on the steel sheet, which significantly expands its life span and resilience.

Advantages of PPGI and PPGL

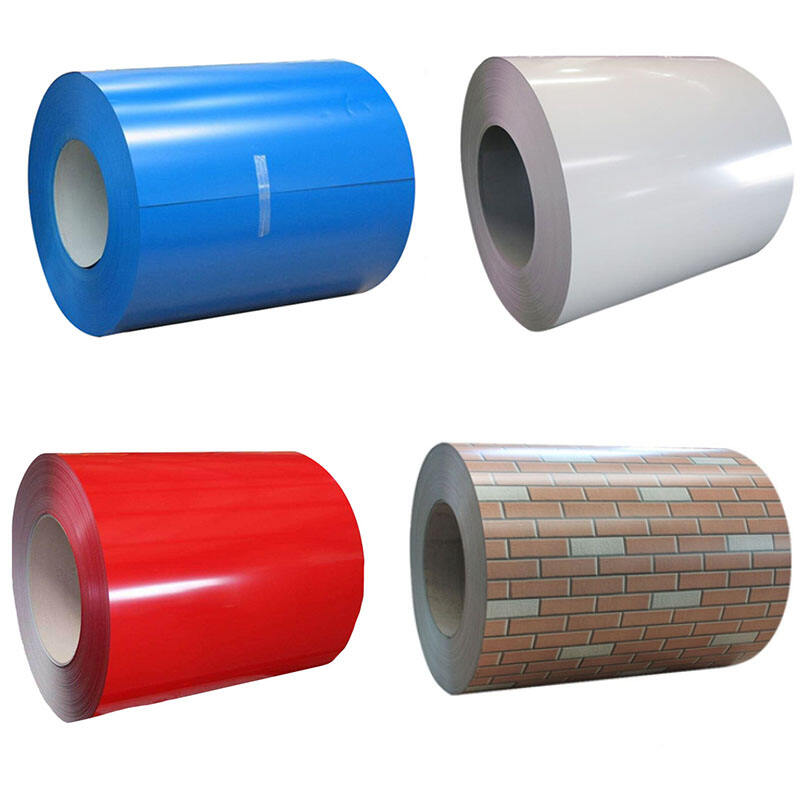

Below are the advantages of using PPGI and PPGL coatings. They offer excellent rust protection, are simple to clean and maintain. They also come in a wide range of colors styles and textures which make them ideal to use for such interior or exterior applications because it the variations of taste.

Innovation with safety standards

Creativity and protection in the PPGI and PPGL coatings to aspect. The tech behind these coats is ever-evolving, as manufacturers switch to eco-friendly powder coatings (also free of nasties like lead or chromium). It means that all of the coatings they supply are completely safe whether being used in private homes or public spaces.

Usage and Done Way

These are some coatings applications of PPGI and PPGL; in areas like construction, automotive or home appliances industries. Because these coatings provide protection in a different way than others on the market, they are used for parts as diverse as roofing and siding material down to fencing materials. When it comes to selecting the ppgi coil or PPGL sheets for your project, all you may look up are the type of sheet with size and thickness according to one's own requirement and possibly sometimes required by customer guidance.

Quality over Everything

It is similar for coatings like PPGI and PPGL without a good quality of service, min e the resources invested. Choose best-rated manufacturers and suppliers like ROGO, so that; You will likely place to top high-quality coatings on steel sheets sourced from world-class sources at appropriate time with king-like supports prior buying a product do your homework by asking references based off reviews of websites matching prices/warranties as it is merely not only keeping away yourself out of unsatisfied purchases but also getting the best cost-to-value ratio.

Versatility of PPGI and PPGL

The list of things that PPGI and PPGL coating to do are endless from roofs on top, cladding on the sides, floors or soft interior elements. The specific uses of these coatings are an important subject in the automotive industry being used mainly on car bodies, frames components. Not only that, but they are extremely easy to install and replace which is why so many DIYers just screaming out of pleasure working with them for practically anything.

To sum up, PPGI and PPGL are differ from one another in having some special coatings that provide additional difference in guard to counter corrosion. The two sprays on coatings are used specifically for certain applications and both come with their own set of benefits. Comparing with the top painting, skin surface type and also steel levels will give you a higher quality set up along in both PPGI as well as PPGL.